Quality Control Test Equipment

Coefficient of Friction [CoF; Mobility, Lubricity] Test Stations ***NEW UPDATES IN PROGRESS***

Testers

Description

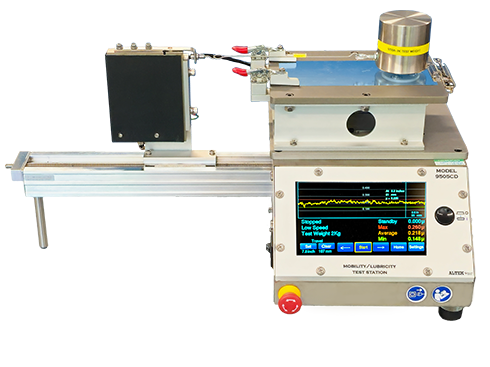

The 9505CD incorporates the reliability of an electronic load cell and digital electronics with an USB output that sends data directly to an ALTEK software displaying real time data with min, max and average results and also a graph of µ -vs– number of sample points.

Click here for additional details and photos.

The 9505CD incorporates the reliability of an electronic load cell and digital electronics with an USB output that sends data directly to an ALTEK software displaying real time data with min, max and average results and also a graph of µ -vs– number of sample points.

Click here for additional details and photos.

Description

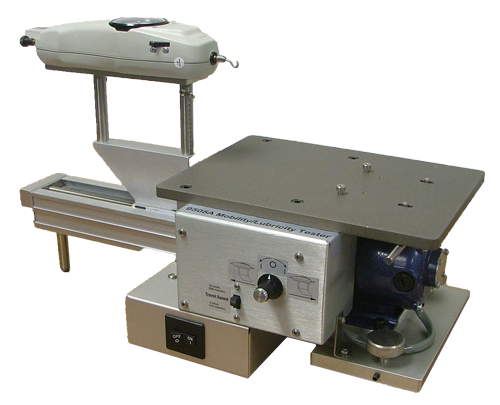

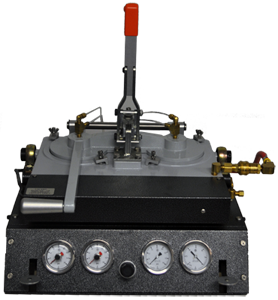

The 9505A is used when electronic test results and outputs are not required. The mechanical gauge can indicate either peak or variable readings and by observing the gauge in variable mode, it is possible to watch fluctuations of the coefficient of friction across the surface of your material.

Click here for additional details and photos.

The 9505A is used when electronic test results and outputs are not required. The mechanical gauge can indicate either peak or variable readings and by observing the gauge in variable mode, it is possible to watch fluctuations of the coefficient of friction across the surface of your material.

Click here for additional details and photos.

Change Parts

Description

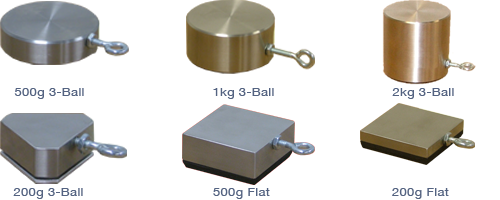

These change parts are used to test the outside mobility/lubricity of a can sample. The 9770A/9771B consists of a calibrated sled weight with three contact balls, and a saddle support, upon which a saddle (that has been specifically manufactured for the can type and size being tested) is mounted. A can is placed over the saddle and the weight is traversed across the outside body of the can.

Click here for additional details and photos.

These change parts are used to test the outside mobility/lubricity of a can sample. The 9770A/9771B consists of a calibrated sled weight with three contact balls, and a saddle support, upon which a saddle (that has been specifically manufactured for the can type and size being tested) is mounted. A can is placed over the saddle and the weight is traversed across the outside body of the can.

Click here for additional details and photos.

Description

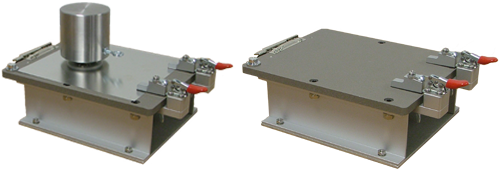

These change parts are used to test the bottom mobility/lubricity of a can sample. The 9791A consists of a calibrated weight (which has been specifically manufactured for the can type and size being tested) and a test platen with polished glass rails. The test weight is placed in the can and the can is traversed across the glass rails.

Click here for additional details and photos.

These change parts are used to test the bottom mobility/lubricity of a can sample. The 9791A consists of a calibrated weight (which has been specifically manufactured for the can type and size being tested) and a test platen with polished glass rails. The test weight is placed in the can and the can is traversed across the glass rails.

Click here for additional details and photos.

Description

These change parts are used to test the surface mobility/lubricity of a can body blank or any other flat sample. The 9793A consists of a test platen with built-in clamps to hold the sample, and a calibrated sled weight. The test weight is traversed across the surface of the flat sample to determine it's mobility/lubricity. Altek can custom manufacture weights to meet specific customer requirements upon request.

Click here for additional details and photos.

These change parts are used to test the surface mobility/lubricity of a can body blank or any other flat sample. The 9793A consists of a test platen with built-in clamps to hold the sample, and a calibrated sled weight. The test weight is traversed across the surface of the flat sample to determine it's mobility/lubricity. Altek can custom manufacture weights to meet specific customer requirements upon request.

Click here for additional details and photos.

Panel Strength Test Stations

Testers

Description

The MODEL 9025A2 Paneling Tester tests the pressure at which a food/utility can will collapse or fail under external pressure.

Click here for additional details and photos.

The MODEL 9025A2 Paneling Tester tests the pressure at which a food/utility can will collapse or fail under external pressure.

Click here for additional details and photos.

Change Parts

Description

The 9794 Change Part holds a food/utility can in place inside the test chamber as the can is being pressurized from the outside. The 9794 consists of a base and an adjustable height post to support the bottom of the inverted sample.

Click here for additional details and photos.

The 9794 Change Part holds a food/utility can in place inside the test chamber as the can is being pressurized from the outside. The 9794 consists of a base and an adjustable height post to support the bottom of the inverted sample.

Click here for additional details and photos.

Can/End Buckling Test Stations

Testers

Description

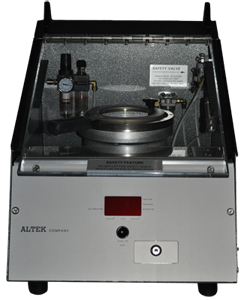

The MODEL 9009G Can Buckling Test Station is used to determine the pressure at which the bottom dome of a beverage can fails. The failure pressure is registered upon reversal of the can's bottom dome.

Click here for additional details and photos.

The MODEL 9009G Can Buckling Test Station is used to determine the pressure at which the bottom dome of a beverage can fails. The failure pressure is registered upon reversal of the can's bottom dome.

Click here for additional details and photos.

Description

The MODEL 9009C4 End Buckling Test Station is used to determine the pressure at which an unseamed beverage end fails. The failure pressure is registered upon buckle or tab blowout of the free end.

Click here for additional details and photos.

The MODEL 9009C4 End Buckling Test Station is used to determine the pressure at which an unseamed beverage end fails. The failure pressure is registered upon buckle or tab blowout of the free end.

Click here for additional details and photos.

Description

The MODEL 9009C5 Can Buckling Test Station is used to determine the pressure at which the bottom dome of a beverage can fails. The failure pressure is registered upon reversal of the can's bottom dome.

Click here for additional details and photos.

The MODEL 9009C5 Can Buckling Test Station is used to determine the pressure at which the bottom dome of a beverage can fails. The failure pressure is registered upon reversal of the can's bottom dome.

Click here for additional details and photos.

Description

The MODEL 9009F2 Can Growth/Buckling Test Station is used to measure growth of the can relative to the internal pressure. The 9009F2 also has the ability to determine the pressure at which the bottom dome of a beverage can fails.

Click here for additional details and photos.

The MODEL 9009F2 Can Growth/Buckling Test Station is used to measure growth of the can relative to the internal pressure. The 9009F2 also has the ability to determine the pressure at which the bottom dome of a beverage can fails.

Click here for additional details and photos.

Description

The MODEL 9009H4 End Buckle / Tab Blowout / Vent Test Station is used to determine the pressure at which unseamed beverage ends fail. Failure pressure is registered upon buckle or tab blowout of the free end. The 9009H4 also has the ability to perform vent tests, in which the test is terminated upon the opening of the tab.

Click here for additional details and photos.

The MODEL 9009H4 End Buckle / Tab Blowout / Vent Test Station is used to determine the pressure at which unseamed beverage ends fail. Failure pressure is registered upon buckle or tab blowout of the free end. The 9009H4 also has the ability to perform vent tests, in which the test is terminated upon the opening of the tab.

Click here for additional details and photos.

Change Parts

Description

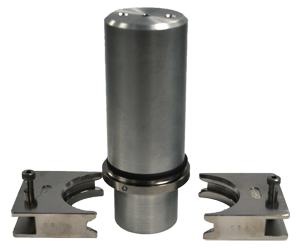

The 9800 Change Part holds a necked-in can in place as it is being pressurized. The 9800 consists of a displacement plug over which the can is placed; an optional plug extender for use with a second height of can; a pair of jaws which clamp the sample in place against the displacement plug during testing.

Click here for additional details and photos.

The 9800 Change Part holds a necked-in can in place as it is being pressurized. The 9800 consists of a displacement plug over which the can is placed; an optional plug extender for use with a second height of can; a pair of jaws which clamp the sample in place against the displacement plug during testing.

Click here for additional details and photos.

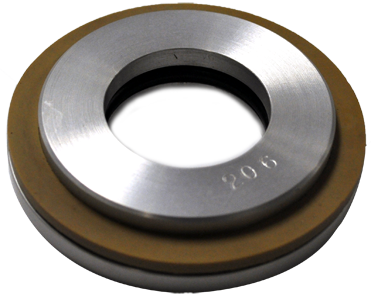

Description

The 9820 Change Part holds a straight wall can in place as it is being pressurized. The 9820 consists of a displacement plug over which the can is placed; an optional plug extender for use with a second height of can; a pair of jaws which clamp the sample in place against the displacement plug during testing and a seal assembly.

Click here for additional details and photos.

The 9820 Change Part holds a straight wall can in place as it is being pressurized. The 9820 consists of a displacement plug over which the can is placed; an optional plug extender for use with a second height of can; a pair of jaws which clamp the sample in place against the displacement plug during testing and a seal assembly.

Click here for additional details and photos.

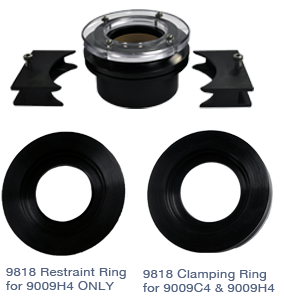

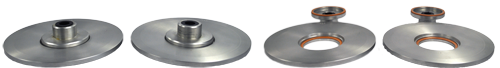

Description

The 9818 Change Parts hold an unseamed end in place as it is being pressurized. The 9818 consist of an end holder base with a molded synthetic gasket on which the free end rests, a clamping ring, which is placed on top of the end and a pair of jaws, which clamp the sample between the clamping ring and end holder during testing.

The 9818 is also available with a clamping ring that restrains the counter-sink area and prevents the end from buckling, necessary for the testing of Tab Blowout or Vent failures.

Click here for additional details and photos.

The 9818 Change Parts hold an unseamed end in place as it is being pressurized. The 9818 consist of an end holder base with a molded synthetic gasket on which the free end rests, a clamping ring, which is placed on top of the end and a pair of jaws, which clamp the sample between the clamping ring and end holder during testing.

The 9818 is also available with a clamping ring that restrains the counter-sink area and prevents the end from buckling, necessary for the testing of Tab Blowout or Vent failures.

Click here for additional details and photos.

Description

The 9845 consists of a measurement fixture encompassed in a height tube. To obtain growth measurements, the 9845 is placed over the can and onto a plate that is parallel to the seating plane of the can. The gauge fixture is then seated properly to align itself to the can and a measurement sequence is initiated.

Click here for additional details and photos.

The 9845 consists of a measurement fixture encompassed in a height tube. To obtain growth measurements, the 9845 is placed over the can and onto a plate that is parallel to the seating plane of the can. The gauge fixture is then seated properly to align itself to the can and a measurement sequence is initiated.

Click here for additional details and photos.

Aerosol Test Stations

Testers

Description

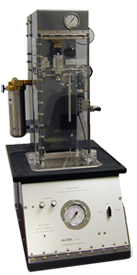

The MODEL 9408B1 Hydrostatic Tester is used to test the buckle and burst pressures of CSMA 1" curl aerosol cans. The 9408B1 tests top dome buckle, bottom buckle, and double seam burst pressures for aerosol cans. When used with an optional Change Part, the 9408B1 can also test aerosol can side seam or sidewall failure.

Click here for additional details and photos.

The MODEL 9408B1 Hydrostatic Tester is used to test the buckle and burst pressures of CSMA 1" curl aerosol cans. The 9408B1 tests top dome buckle, bottom buckle, and double seam burst pressures for aerosol cans. When used with an optional Change Part, the 9408B1 can also test aerosol can side seam or sidewall failure.

Click here for additional details and photos.

Description

The MODEL 9408D2 Hydrostatic Tester is used to test the buckle and burst pressures of CSMA 1" curl aerosol cans. The 9408D2 tests top dome buckle, bottom buckle, and double seam burst pressures for aerosol cans. When used with an optional Change Part, the 9408D2 can also test aerosol can side seam or sidewall failure.

Click here for additional details and photos.

The MODEL 9408D2 Hydrostatic Tester is used to test the buckle and burst pressures of CSMA 1" curl aerosol cans. The 9408D2 tests top dome buckle, bottom buckle, and double seam burst pressures for aerosol cans. When used with an optional Change Part, the 9408D2 can also test aerosol can side seam or sidewall failure.

Click here for additional details and photos.

Description

The MODEL 9016 Buckle and Flow Tester is used to determine the pressure required to buckle the top dome of a Pressure Release Mechanism (PRM) aerosol can. The 9016 also indicates the volume of air flow through the vent after buckling.

Click here for additional details and photos.

The MODEL 9016 Buckle and Flow Tester is used to determine the pressure required to buckle the top dome of a Pressure Release Mechanism (PRM) aerosol can. The 9016 also indicates the volume of air flow through the vent after buckling.

Click here for additional details and photos.

Change Parts

Description

The 9760 Change Parts constrain an aerosol can as it is being pressurized from the inside. The 9760 consists of a cage fixture, with fitted top and bottom inserts, that quick-clamps around a can before the can is mounted in the tester.

The top insert is machined to fit the can neck, while the bottom insert is molded to fit the bottom of the samples to be tested. These inserts are mounted on rings, which are held together with threaded connecting rods, and the bottom ring slides via an adjustable clamp. The sample is placed inside the cage and the clamp is then closed, securing the sample between the top and bottom inserts.

Click here for additional details and photos.

The 9760 Change Parts constrain an aerosol can as it is being pressurized from the inside. The 9760 consists of a cage fixture, with fitted top and bottom inserts, that quick-clamps around a can before the can is mounted in the tester.

The top insert is machined to fit the can neck, while the bottom insert is molded to fit the bottom of the samples to be tested. These inserts are mounted on rings, which are held together with threaded connecting rods, and the bottom ring slides via an adjustable clamp. The sample is placed inside the cage and the clamp is then closed, securing the sample between the top and bottom inserts.

Click here for additional details and photos.

Leak Testers

Testers

Description

The MODEL 9001HP Leak Tester allows beverage ends to be tested for leaks in the score and tab area. The MODEL 9001LP Leak & Buckling Tester is used to determine the buckling resistance of food/utility ends and to test for the presence of leaks in food/utility ends.

Click here for additional details and photos.

The MODEL 9001HP Leak Tester allows beverage ends to be tested for leaks in the score and tab area. The MODEL 9001LP Leak & Buckling Tester is used to determine the buckling resistance of food/utility ends and to test for the presence of leaks in food/utility ends.

Click here for additional details and photos.

Change Parts

Description

The 9748 Change Parts hold a round end in place as a vacuum is applied to the product side of the end. The 9748 consists of a lower adapter and gasket which fit onto the test unit and into which the end is placed, and an upper cup and gasket that clamps down on the end during operation to affect a seal.

Click here for additional details and photos.

The 9748 Change Parts hold a round end in place as a vacuum is applied to the product side of the end. The 9748 consists of a lower adapter and gasket which fit onto the test unit and into which the end is placed, and an upper cup and gasket that clamps down on the end during operation to affect a seal.

Click here for additional details and photos.

Description

The 9837 Change Parts hold an end in place as pressure is applied to the product side of the end. The 9837 consists of a lower adapter plate and gasket which fit onto the test unit and an upper cup and gasket that clamps down on the end during operation to affect a seal.

Click here for additional details and photos.

The 9837 Change Parts hold an end in place as pressure is applied to the product side of the end. The 9837 consists of a lower adapter plate and gasket which fit onto the test unit and an upper cup and gasket that clamps down on the end during operation to affect a seal.

Click here for additional details and photos.

Axial Load Test Stations

Testers

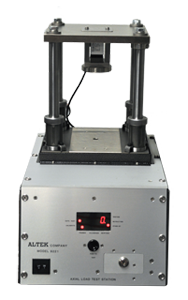

Description

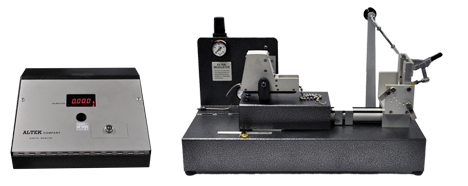

The MODEL 9221C2 Axial Load Test Station is used to determine the load carrying capacity of food/utility and beverage cans. The 9221C2 displays the peak force that is applied to a sample before it collapses or otherwise fails.

Click here for additional details and photos.

The MODEL 9221C2 Axial Load Test Station is used to determine the load carrying capacity of food/utility and beverage cans. The 9221C2 displays the peak force that is applied to a sample before it collapses or otherwise fails.

Click here for additional details and photos.

Description

The MODEL 9221CA2 Axial Load Test Station is used to determine the load carrying capacity of light-weighted beverage cans. The 9221CA2 displays the peak force that is applied to a sample before it collapses or otherwise fails.

Click here for additional details and photos.

The MODEL 9221CA2 Axial Load Test Station is used to determine the load carrying capacity of light-weighted beverage cans. The 9221CA2 displays the peak force that is applied to a sample before it collapses or otherwise fails.

Click here for additional details and photos.

Description

The MODEL 9221DA4 Axial Load Test Station is used to determine the load carrying capacity of a sample. The 9221DA4 displays the peak force that is applied to a sample before it collapses or otherwise falls.

Click here for additional details and photos.

The MODEL 9221DA4 Axial Load Test Station is used to determine the load carrying capacity of a sample. The 9221DA4 displays the peak force that is applied to a sample before it collapses or otherwise falls.

Click here for additional details and photos.

Change Parts

Description

The 9814 Change Parts hold a necked-in can in place as it is being compressed. The 9814 consists of a can locator with centering pin and optional locator extender for use with a second height of can. The 9814 Change Parts are designed and manufactured to fit the neck contour of the sample EXACTLY in order to prevent neck failure during testing of the sample’s sidewall.

Click here for additional details and photos.

The 9814 Change Parts hold a necked-in can in place as it is being compressed. The 9814 consists of a can locator with centering pin and optional locator extender for use with a second height of can. The 9814 Change Parts are designed and manufactured to fit the neck contour of the sample EXACTLY in order to prevent neck failure during testing of the sample’s sidewall.

Click here for additional details and photos.

Description

The 9836 Change Parts hold an un-necked can in place as it is being compressed. The 9836 consists of a can locator with centering pin and an optional locator extender of use with a second height of can. The 9836 Change Parts are designed and manufactured to hold the sidewalls of an un-necked can parallel to the direction of the applied load during testing of the sample’s sidewall.

Click here for additional details and photos.

The 9836 Change Parts hold an un-necked can in place as it is being compressed. The 9836 consists of a can locator with centering pin and an optional locator extender of use with a second height of can. The 9836 Change Parts are designed and manufactured to hold the sidewalls of an un-necked can parallel to the direction of the applied load during testing of the sample’s sidewall.

Click here for additional details and photos.

Pop/Tear Test Stations

Testers

Change Parts

Enamel Raters

Raters

Change Parts

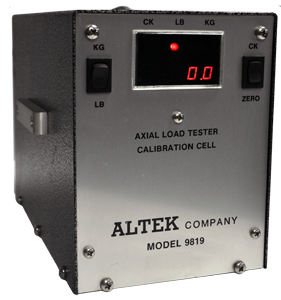

Calibration Equipment